Die Science: Piercing, cutting aluminum without slivers

Slivers are the result of the aluminum interfacing with the cutting sections or punches. To reduce the production of slivers the severity of friction at the point where the two surfaces interface must be reduced. The general rule for cutting materials is the softer the metal the smaller the cutting clearance.

Shearing and flanging conditions. Fig. 12. Surface of sheared edge

Die Science - Splitting in A Stretch Flange - The Fabricator

Fine Sporting Arms Auction September 11 & 12, 2023 by Guyette

Influence of cutting parameters on mechanisms causing slug pulling

I found this while using my metal detector. Can anyone help? It's

Optimization of trimming process in cold forging of steel bolts by

SURGICAL ONLINE Superior Young Tongue Forceps

Bertrand Piccard's Laps Around the World

Engineering Angle: Die wear of 3D-printed tools when stamping

PDF) Notch Shear Cutting of Aluminum Alloys

Die Science: Piercing, cutting aluminum without slivers

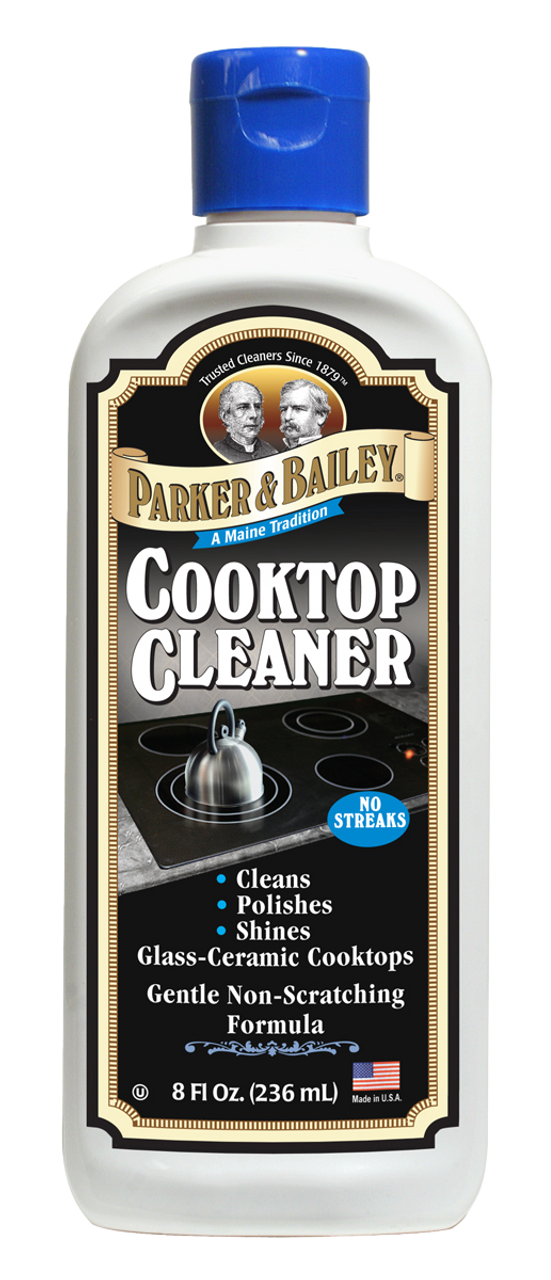

Cutting lubricant formulated for use on aluminum

I found this while using my metal detector. Can anyone help? It's

Shearing process: blanking and piercing [1]