Steel - Casting, Alloy, Heat Treatment

Steel - Casting, Alloy, Heat Treatment: The simplest way to solidify liquid steel is to pour it into heavy, thick-walled iron ingot molds, which stand on stout iron plates called stools. During and after pouring, the walls and bottom of the mold extract heat from the melt, and a solid shell forms, growing approximately with the square root of time multiplied by a constant. The value of the constant depends on the heat flux between the already solidified shell and the cooling media surrounding it and is actually equivalent to the solidified shell’s thickness after one minute—namely, about 20 millimetres when solidifying steel. Accordingly, the ingot

Steel, alloy of iron and carbon in which the carbon content ranges up to 2 percent (with a higher carbon content, the material is defined as cast iron). By far the most widely used material for building the world’s infrastructure and industries, it is used to fabricate everything from sewing needles to oil tankers.

Typical microstructures of heat-treated sand-cast test bars: (a) 3 mm

The reason of heat treatment for Steel casting parts

Heat Treatment Fixture 1.4849 Heat-Resistant Steel Tray Alloy Steel Grate Board Casting Furnace Base Trays - China Heat Treatment Fixture, Heat-Resistant Steel

Heat Treatment Fixtures Heat Resistant Casting Nickel Alloy - China Cast Basket, Investment Casting

Effect of Heat Treatment on the Mechanical Properties of Squeeze-Cast Al–5Si–3Cu Alloy for Automotive Applications

Metal Heat Treatment, Casting Heat Treatment

Heat Treatment Process Of Hardened Steel And Pre-Hardened Steel - Minghe Casting

Heat treatment of steel-bonded TiC Ferro Alloy

Heat Treating Aluminium [Easy DIY method]

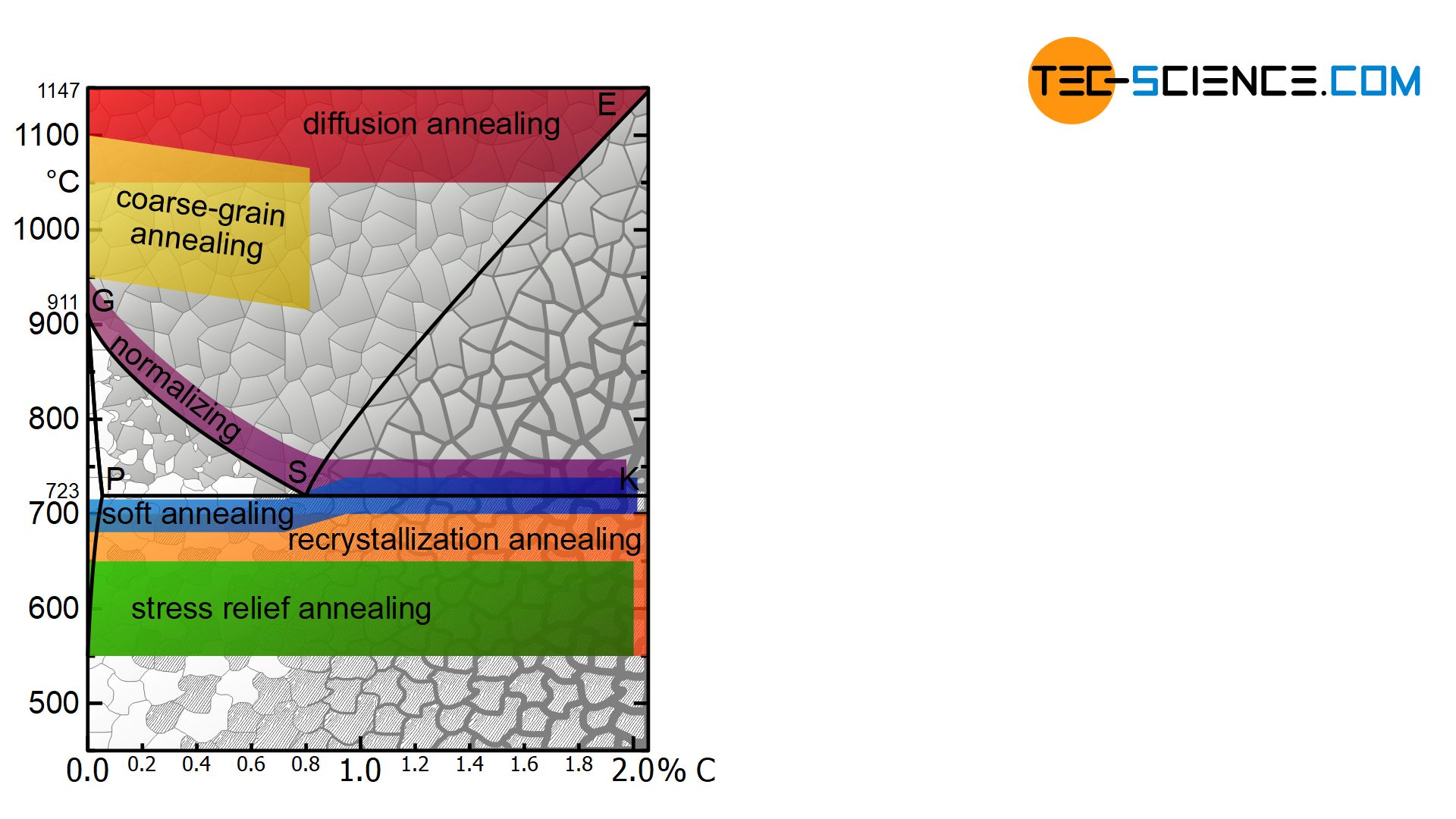

Overview of heat treatment of steel - tec-science

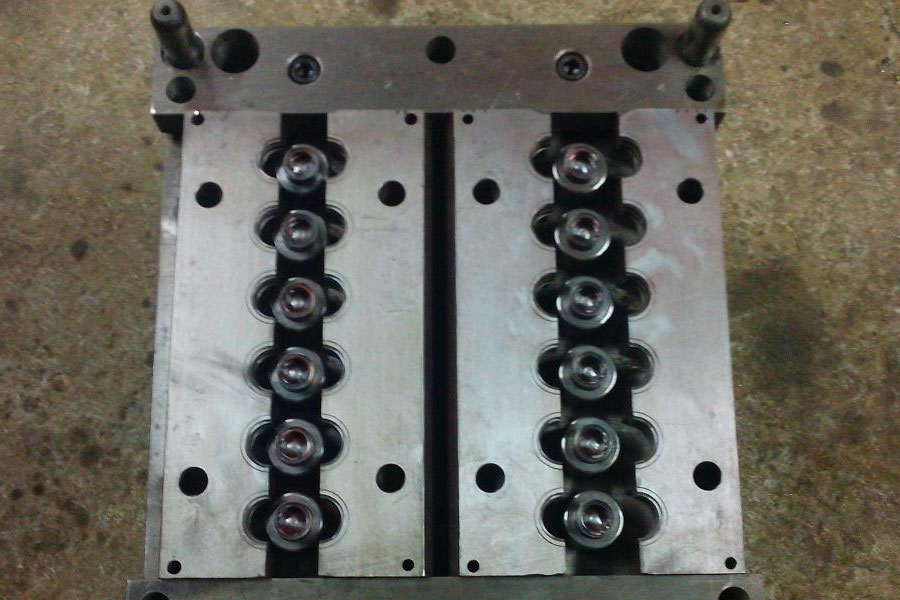

Aluminum die casting process

Heat Treatment Process for Metal Casting: Why it is so important?

Heat Treatment

Materials, Free Full-Text

Heat Treatment of Steel Forgings