Standard Staple Yarn Spinning Procedures - Textile School

Yarn making from staple fibers involves picking (opening, sorting, cleaning, blending), carding and combing (separating and aligning), drawing (re-blending), drafting (drawing into a long strand) and spinning (further drawing and twisting). Silk and synthetic filaments are produced by a less extensive procedure. Current high-production yarn-making operations are performed on integrated machines that perform this entire sequence as one combined operation.

a knowledge-base repository of textile articles

Yarn making from staple fibers involves picking (opening, sorting, cleaning, blending), carding and combing (separating and aligning), drawing (re-blending), drafting (drawing into a long strand) and spinning (further drawing and twisting). Silk and synthetic filaments are produced by a less extensive procedure. Current high-production yarn-making operations are performed on integrated machines that perform this entire sequence as one combined operation.

Kingbird have over 20 years experience in core spun yarn industry.

Staple Yarn Spinning Yarn formation techniques for staple yarn

Standard Staple Yarn Spinning Procedures - Textile School

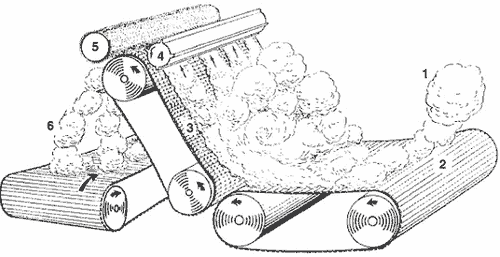

Schematic diagram of melt spinning machine.

Spinning Process Overview: From Fiber Material to Yarn - Testex

staple yarn spinning Archives - Textile School

Ring spinning - Wikipedia

Textile Spinning Process II Making of Staple yarn and Filament yarn

Recent progress in the fabrication and processing of triboelectric yarns - Chen - 2023 - Carbon Neutralization - Wiley Online Library

carding Archives - Josefin Waltin spinner

:max_bytes(150000):strip_icc()/paper-fringe-216-d111394_vert-f3d323f2b334449f8642846b9b1b019e.jpg)