Silicone Curing Sheets - Parchment Paper

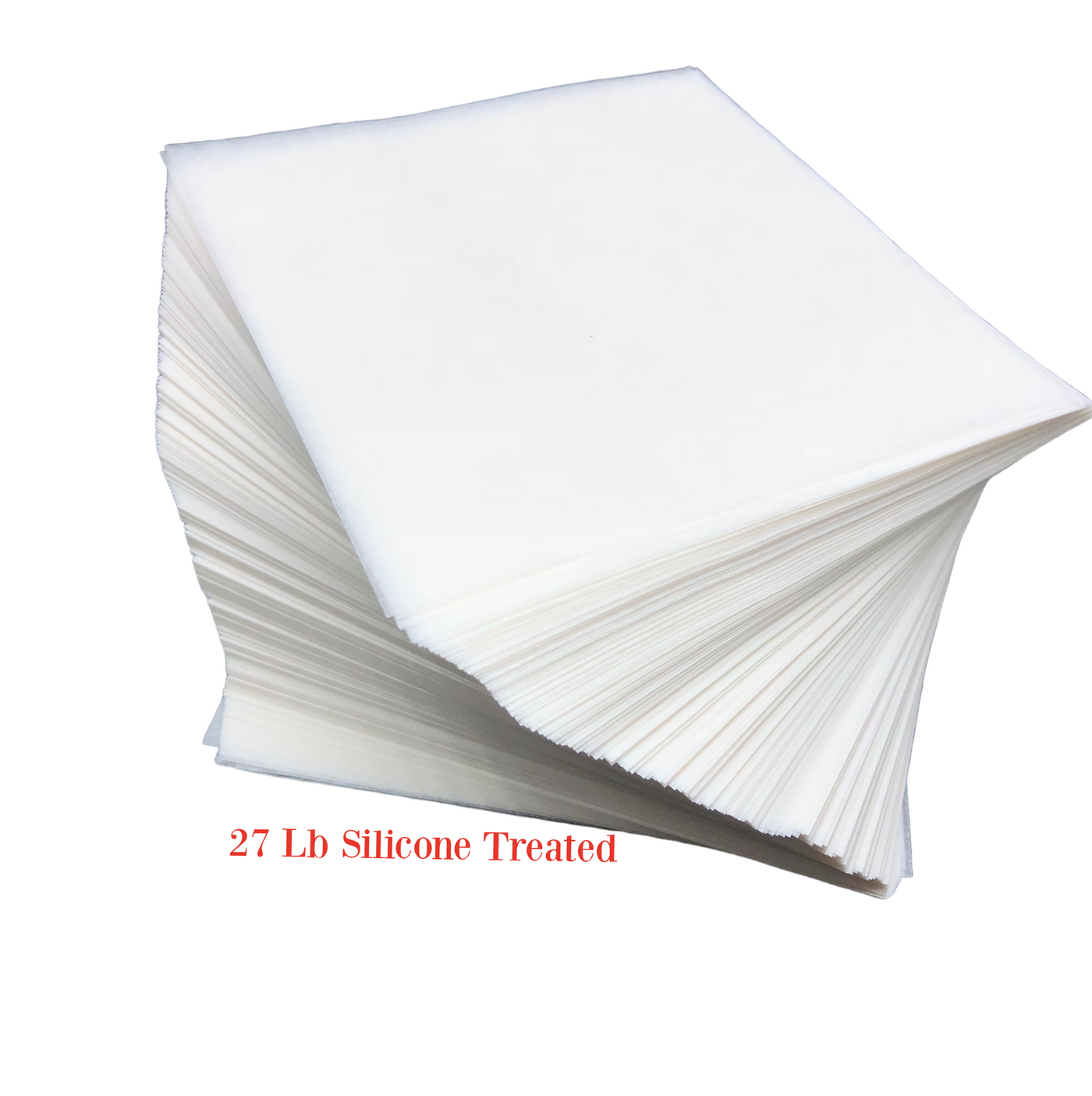

The high quality Silicone Parchment Paper sheets are perfect for curing direct-to-garment inks on fabric with a heat press. The silicone coating keeps ink residue from building up on the paper's surface and has a big surface area of 16" x 24" and sold in 100 sheets or 1000 sheets.

NOTE: Not recommended for pretreatment curing

These sheets are perfect for curing direct-to-garment inks on fabric with a heat press. The silicone coating keeps ink residue from building up on the paper's surface, allowing you to reuse sheets multiple times. The sheets may brown with use but will not cause your ink to discolor or leave a glossy finish behind.

Silicone Parchment Paper for use with heat pressing and setting DTG inks. Sheets are 16 x 24 and sold in 100 sheets or 1000 sheets.

Compared to silicone treated papers, parchment papers provide matte finish

Silicone Curing Sheets - Parchment Paper

Minimun Qty, Discount, Add any products to cart 2 +, 5% Off, Add any products to cart 10 +, 12% Off, Add any products to cart 25 +, 20% Off, 27 LB

Silicone Coated #27 LB Parchment Paper Squares Sheets

DTG Quick Tip - Silicone vs. Matte Paper vs. Teflon Sheets

Epson F2100 DTG Ink and Supply

Teflon Sheet 16x20 – DTG Printer Parts

Wholesale CRASPIRE Wax Seal Mat 1.3 Inch 24-Cavity Silicone Pad

13 Curing Sheet Manufacturers in 2024

iColor Kraft Paper Cover/Finishing Sheet

Thin Silicone Paper Two Sided 16x20

Creek Light Pretreat Silicone Release Paper 16x20 – DTG Printer Parts

The DTG Release Paper is the perfect paper to use for heat curing the White Pretreatment for use with your digital garment printer. It can also finish your print as well taking place of the teflon sheet if needed. A much better alternative to parchment paper. Parchment costs about 30 cents per sheet and it can be used 1-3x before tossing it out.

DTG Silicone Release Paper - 16 x 20 - 50ct

PDMS Curing Inhibition on 3D-Printed Molds: Why? Also, How to