Proper Crimping: Identifying Correct Vs. Incorrect Crimps

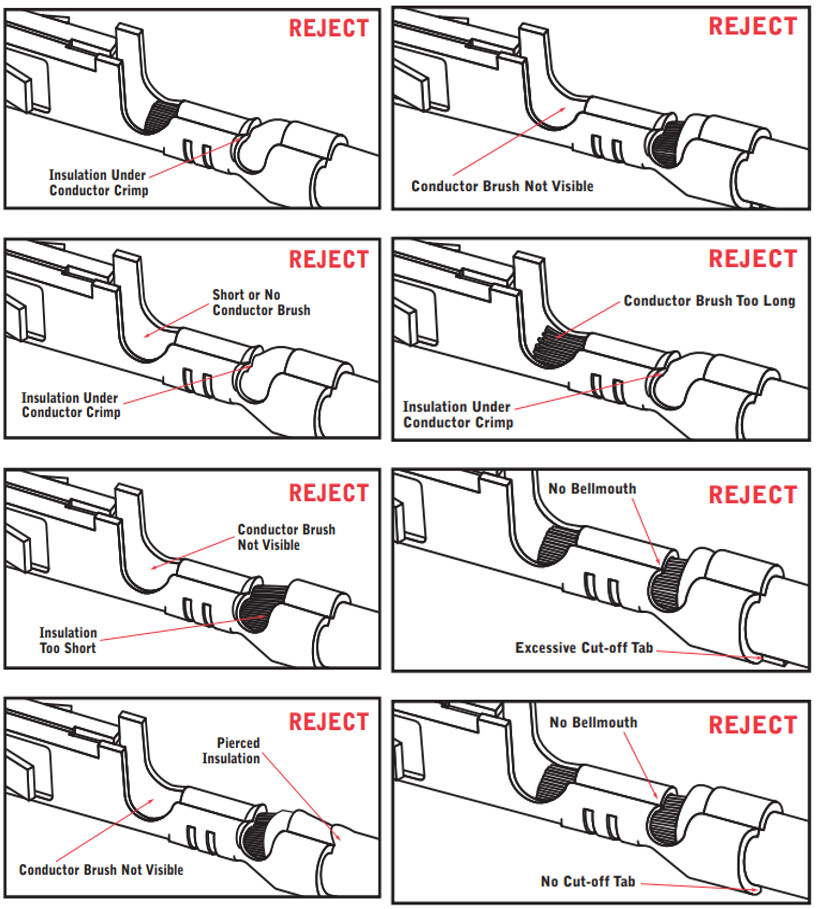

Checking crimp integrity is crucial for quality control. For large scale production, it is important to implement crimp quality checks at the start of production, throughout production, after any tooling change, and when switching to a new reel or bulk bag, as they may be mislabeled or are from a different lot code. The proper crimp tool(ing) is based on the contact being crimped, which includes manufacturer, series, and wire gauge size. Different crimpers or tooling may crimp a contact within

Crimp (joining) - Wikipedia

Crimp vs. Solder vs. Compression: Pros & Cons - RF Industries

Hexagonal Crimp, Cable Lugs, Crimping Tool

But Really, This Is How To Crimp Your Hair

tools - Crimping Connector Issues - Electrical Engineering Stack Exchange

Pinball: Molex Connectors and Terminal Pin Crimping Explained

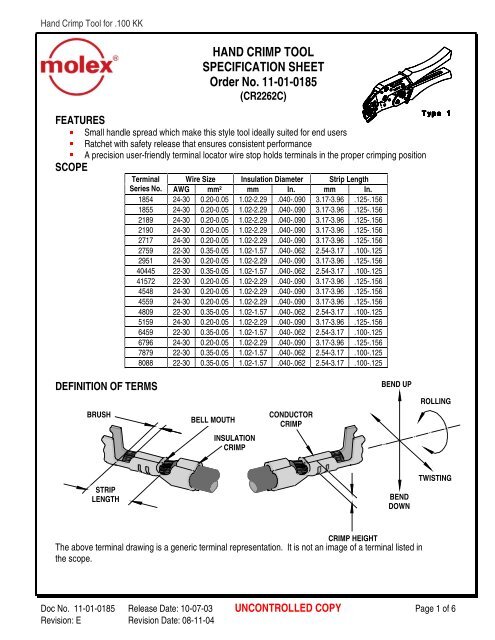

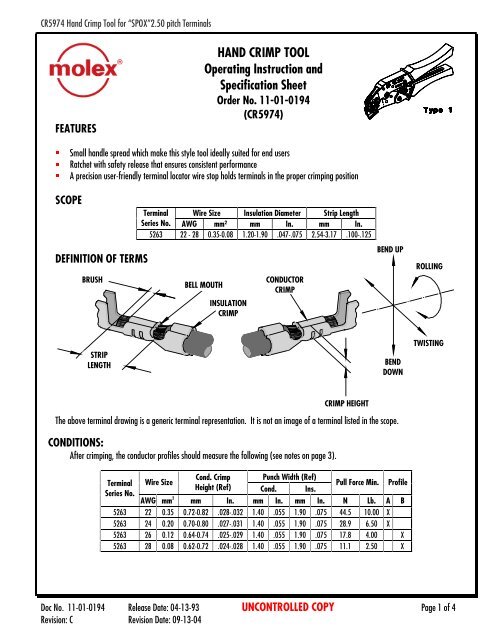

HAND CRIMP TOOL SPECIFICATION SHEET Order No. 11 - Molex

Bright Idea' For Short Detection

HAND CRIMP TOOL Operating Instruction and Specification - Molex

Iwiss Crimping Tool Review: Does it Work? - Bob Vila

KF CPTEC Crimping Tool Set 9 PCS - Ratcheting Wire Crimper - Quick Exchange Jaw for Heat Shrink, Open Barrel, Insulated Electrical Connectors,Insulated and Non-Insulated Ferrules, solar connector

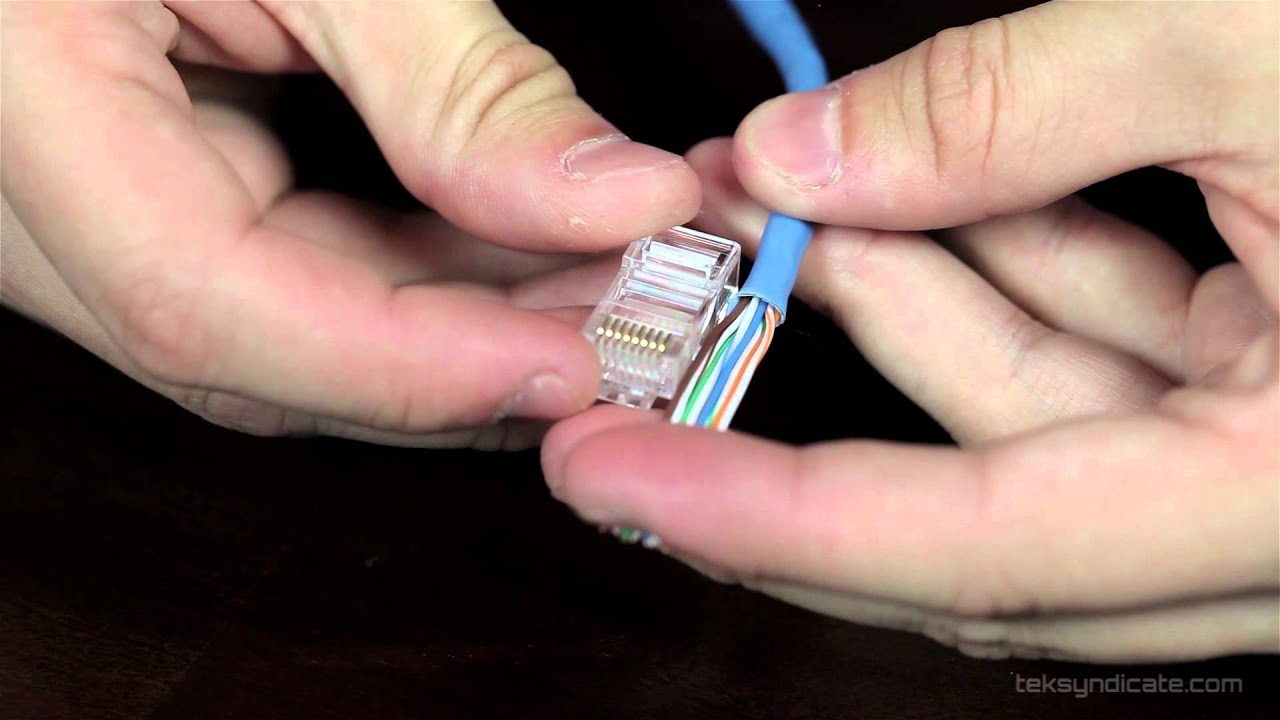

Crimping Cable ! What am I doing Wrong! - Computer Hardware & Server Infrastructure Builds - Lawrence Systems Forums

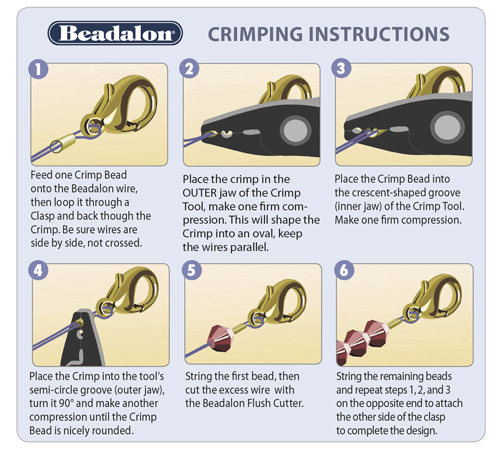

Wire Work Jewelry - Frequently Asked Questions