Processing and Properties of Plastic Lumber

Plastic residue can be processed into composites using wood flour, mineral fillers, plant or synthetic fibers to obtain plastic lumber, a substitute material for natural wood. The composition and processing conditions are largely responsible for the final characteristics of the plastic lumber. Factors such as density, particle size and moisture content in the material to be processed require extruders with specific technical characteristics, in order to reduce the residence time of the plastic inside the equipment, maintain a constant feed rate and ensure good degassing and homogenization of the components. The composites can be manufactured using single-screw, co- or counter-rotating conical or parallel twin-screw extruders. Plastic lumber exhibits different physical and mechanical properties from natural wood, including lower stiffness (elastic modulus) and superior weathering resistance.

The Ultimate Guide to Plastic Lumber for Construction

The Promise and Pitfalls of Plastics in Construction

Recycled Polypropylene-Coffee Husk and Coir Coconut Biocomposites: Morphological, Mechanical, Thermal and Environmental Studies

Timber plastics

Plastic lumber - Wikipedia

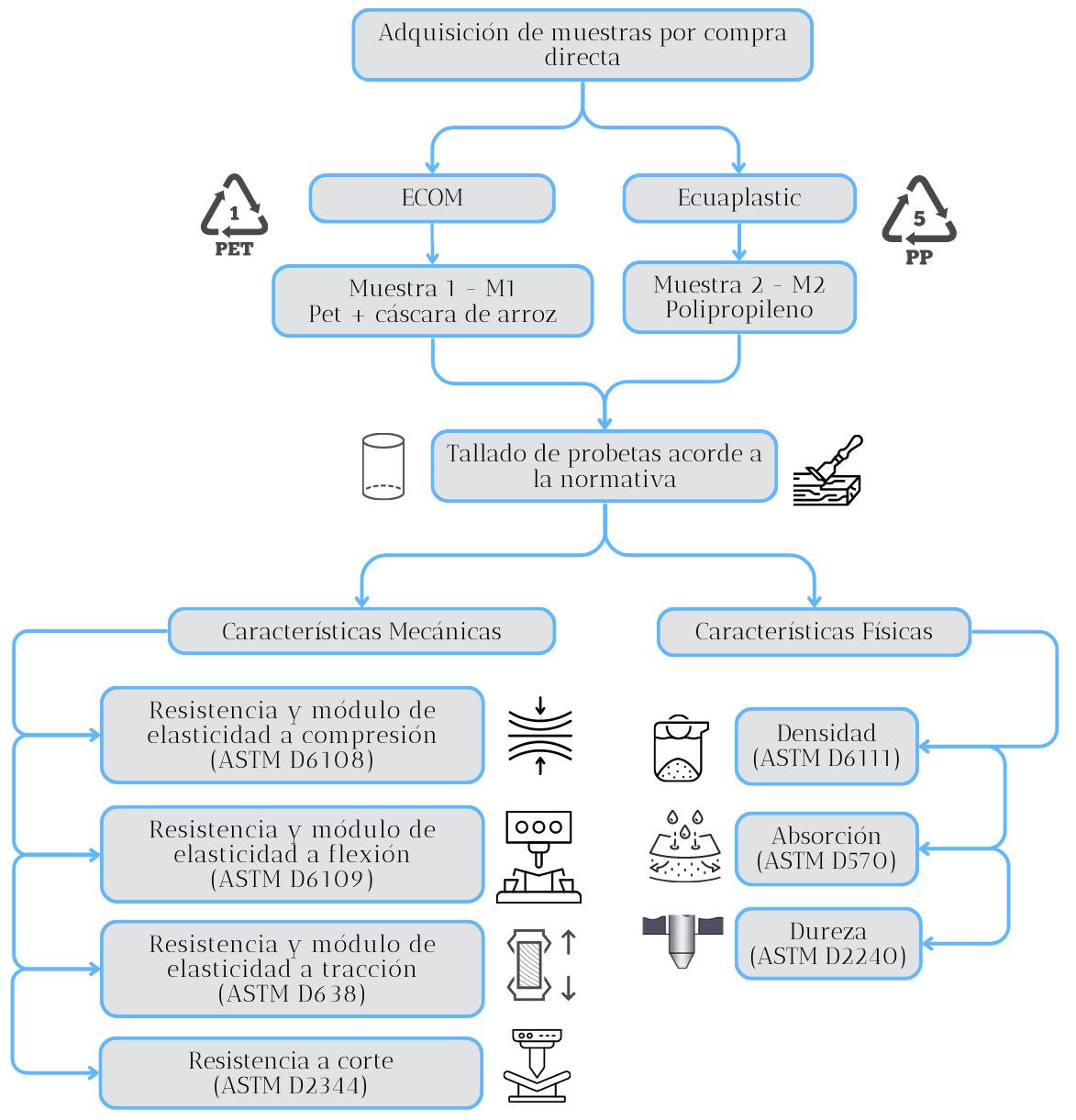

Propiedades físicas y mecánicas de reciclados de plásticos producidos en Ecuador como material de construcción

Recycled Polypropylene-Coffee Husk and Coir Coconut Biocomposites: Morphological, Mechanical, Thermal and Environmental Studies

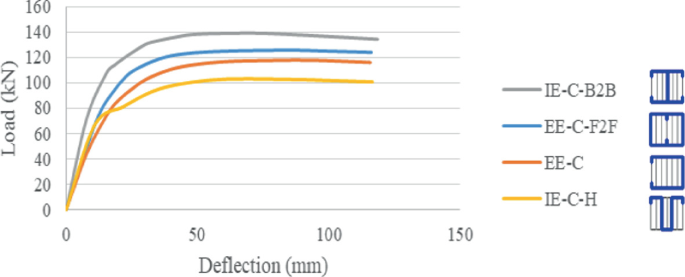

Performance Analysis of CFS Encased Recycled Plastic Laminate Beam

Performance Analysis of CFS Encased Recycled Plastic Laminate Beam

US20130082116A1 - Use of a composition based on thermoplastic resin for the manufacture of railway sleepers - Google Patents

The Difference Between HDPE and Composite Lumber