Metallurgy - Casting, Alloying, Refining

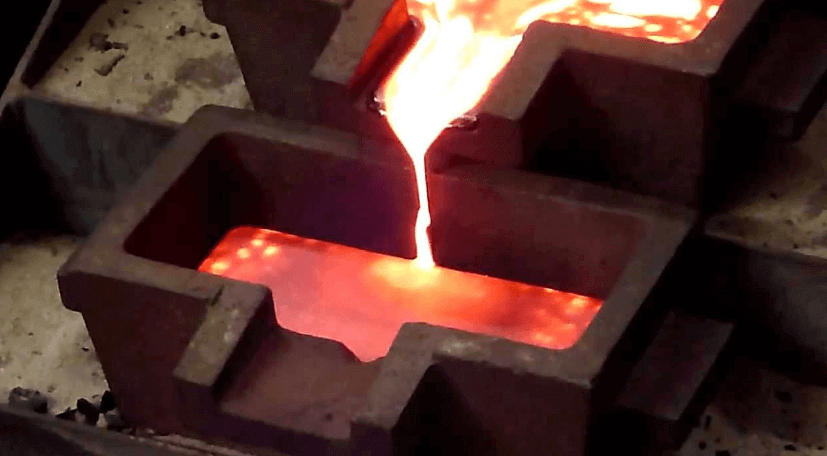

Metallurgy - Casting, Alloying, Refining: Casting consists of pouring molten metal into a mold, where it solidifies into the shape of the mold. The process was well established in the Bronze Age (beginning c. 3000 bc), when it was used to form most of the bronze pieces now found in museums. It is particularly valuable for the economical production of complex shapes, ranging from mass-produced parts for automobiles to one-of-a-kind production of statues, jewelry, or massive machinery. Casting processes differ in how the mold is made and in how the metal is forced into the mold. For metals with a high melting temperature, stable refractory

Metallurgy, art and science of extracting metals from their ores and modifying the metals for use.

What Is Grain Refinement & Why Is It Done?

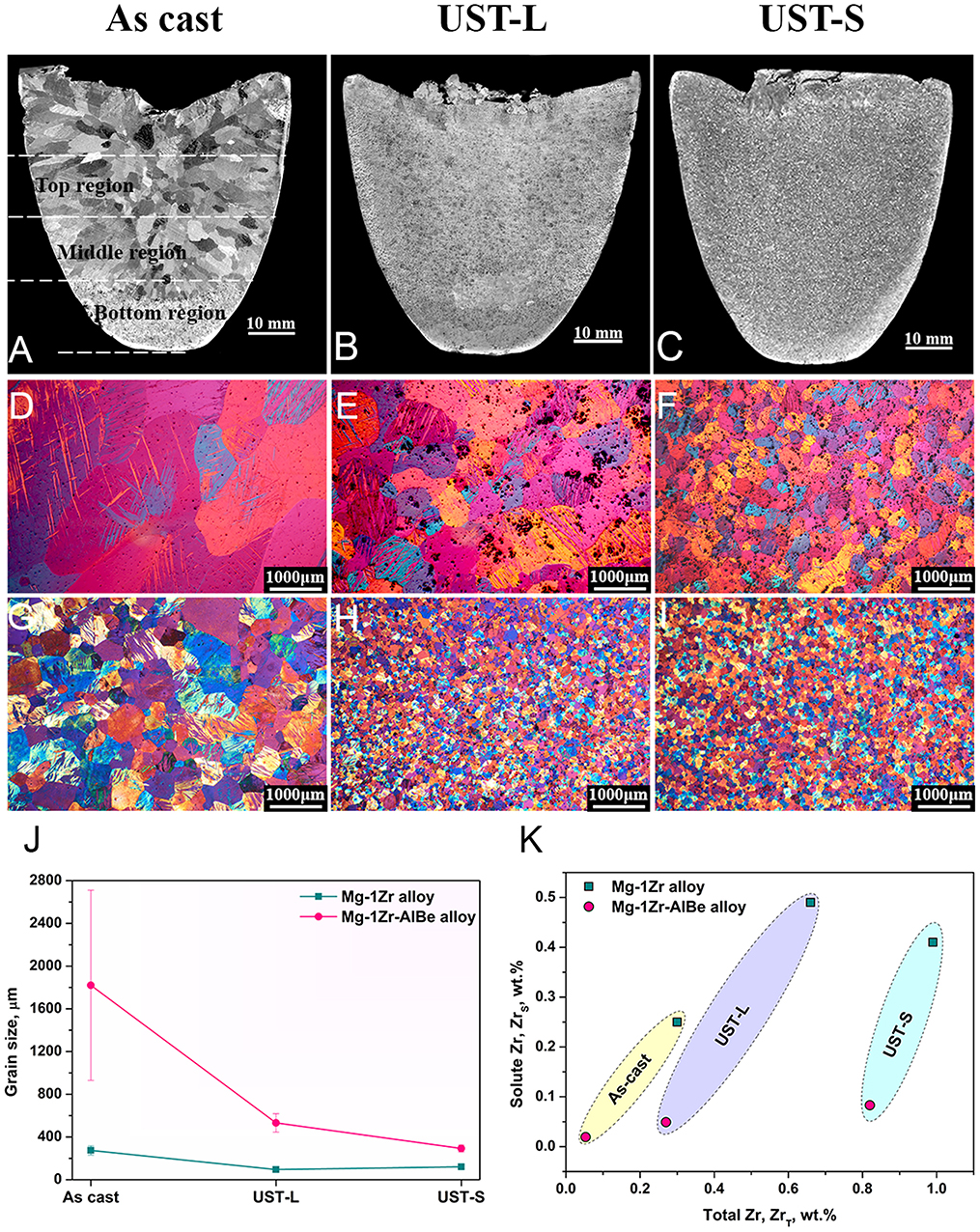

Frontiers The Poisoning Effect of Al and Be on Mg—1 wt.% Zr Alloy and the Role of Ultrasonic Treatment on Grain Refinement

Role of ultrasonic treatment, inoculation and solute in the grain refinement of commercial purity aluminium

Metallurgy - Casting, Alloying, Refining

Melting Gold Alloys for Casting

2024 Casting sexuel and my

Semi-Solid Casting - an overview

Steel - Wikipedia

Casting and Forging - What's the Difference? - Sunrise Metal

a Cooling curves of alloys containing single and combined Sr with

The History & Evolution of Metal & Alloy Casting