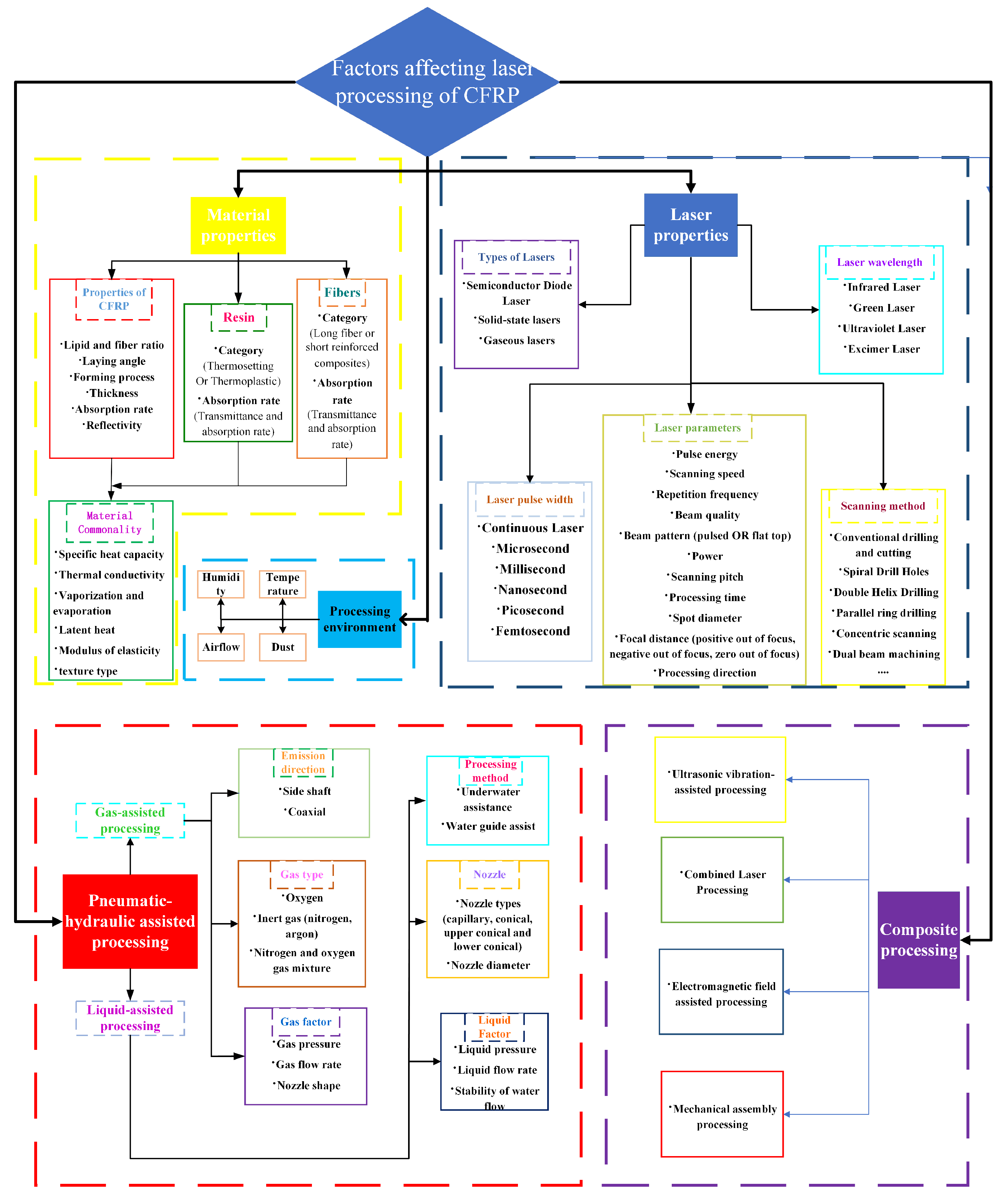

Fiber Lasers in Material Processing

The economic aspects of laser usage in manufacturing that form important criteria in the choice of a suitable laser system for thick-section metal cutting include: high processing speeds, high processing depths, high cut edge quality, and high wall-pug efficiency of the laser system. Consequently, the performance of the high brightness ytterbium fiber laser system in thick-section metal cutting is evaluated based on the maximum achievable cutting speeds, maximum cutting depths possible, and cut edge quality attainable. The maximum processing speeds, maximum processing depths, and resulting cut edge quality are governed by a number of parameters related to the laser system, workpiece specification, and the cutting process. The effects of the processing parameters in the cutting of thick-section stainless steel and mild steel and medium-section aluminium have been reported; optimization of the processing parameters for enhancement of the cut edge quality has been discussed.

Ultrafast Fiber Laser Opens Doors for Additive Manufacturing, Features, Feb 2017

Photonics, Free Full-Text

Best Laser Engraver for Wood: The Complete Guide - Dekcel

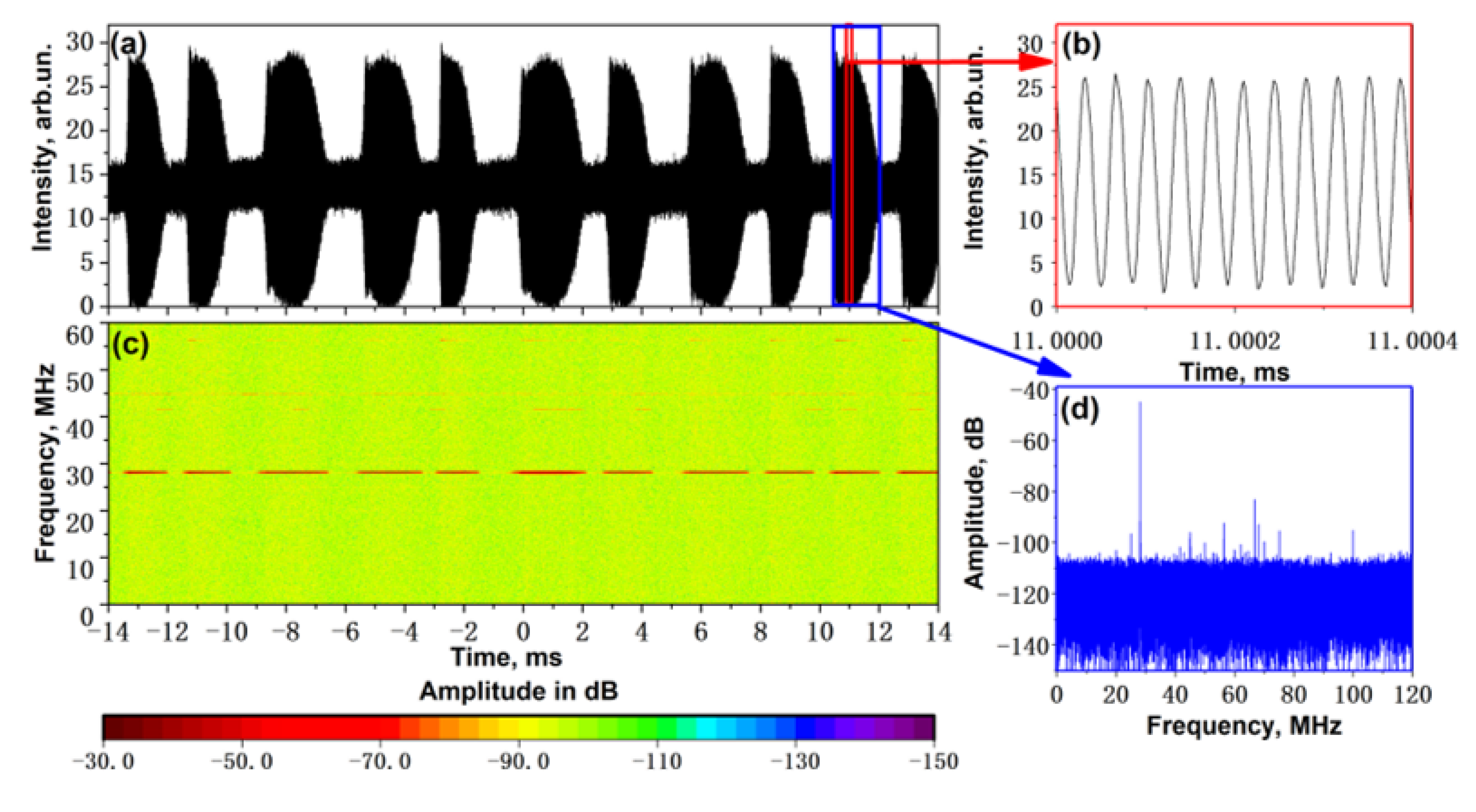

Sensors, Free Full-Text

Fiber Lasers in Material Processing

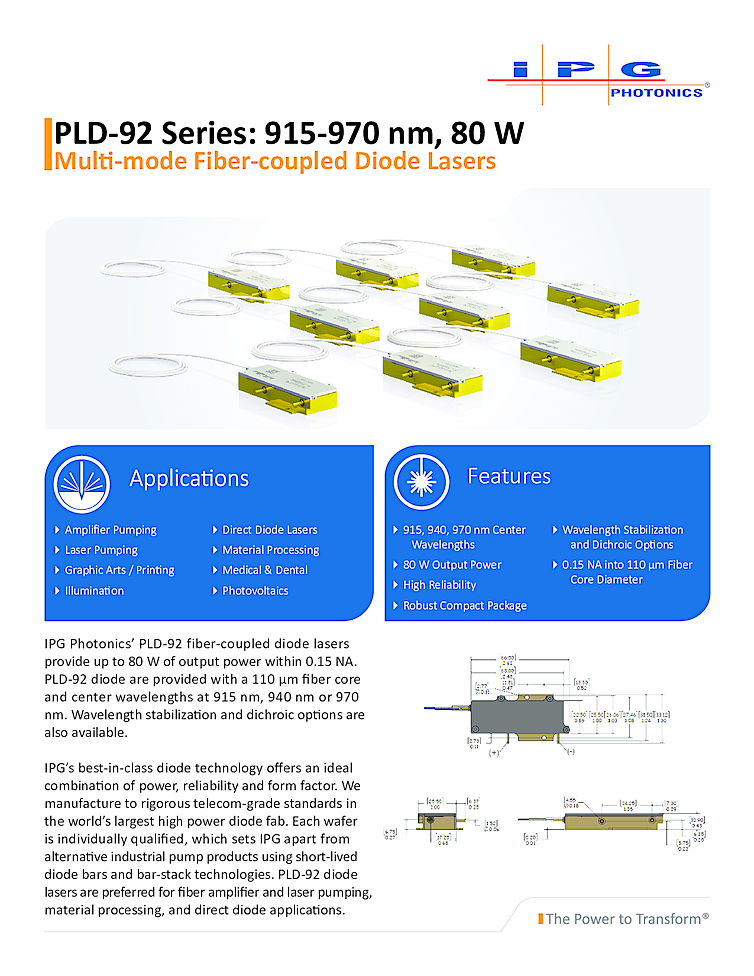

971nm Laser Diode, 80W Fiber-Coupled Module from IPG

Fiber Laser, Fiber Laser Marking Machine

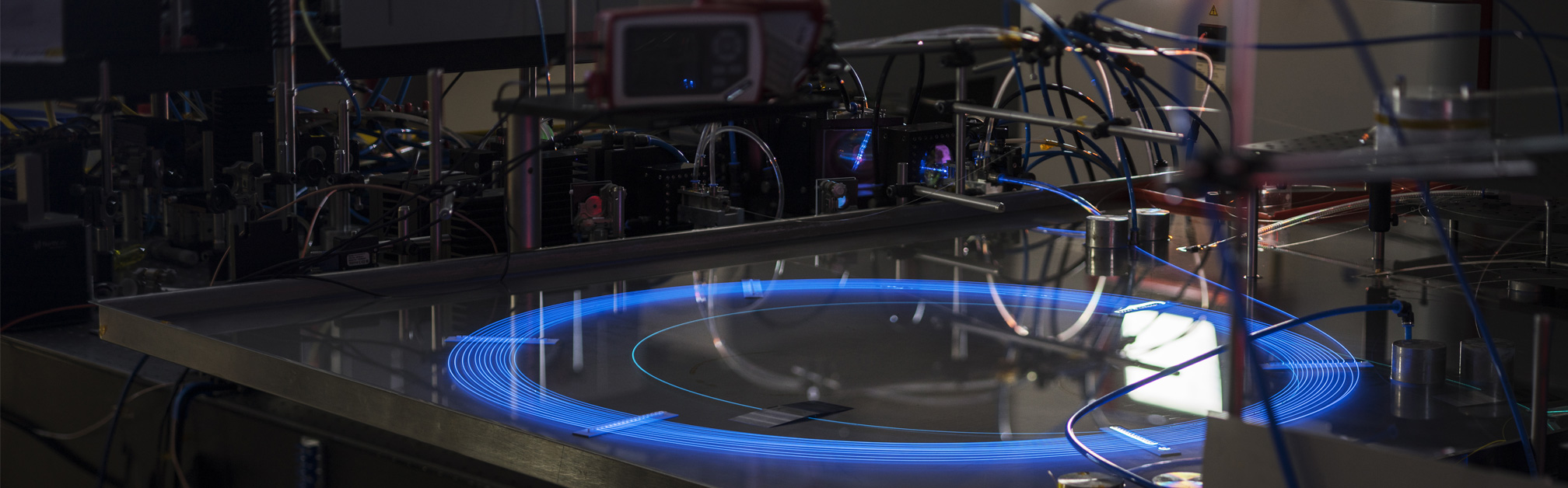

60th Anniversary of Laser - Fraunhofer IOF

Photonics, Free Full-Text

Single-Clad Fiber Laser Market, Centers on Aspects such as Market Growth Market Share, Market Opportunity, and Projected Forecasts Spanning from 2024

Schematic of the fs-laser material processing system, and the

Fiber Lasers Outshine Competing Laser and Non-Laser Technologies

Fiber Lasers Cut Into New Industries, Features, May 2009