Why Should Calcium Carbonate be Surface Coated?

Surface modification is an important way to improve the performance of calcium carbonate, improve its applicability, and expand the market.

Why Should Calcium Carbonate be Surface Coated?

Calcium Carbonate Powder Used In Manufacturing Artificial Marble And S

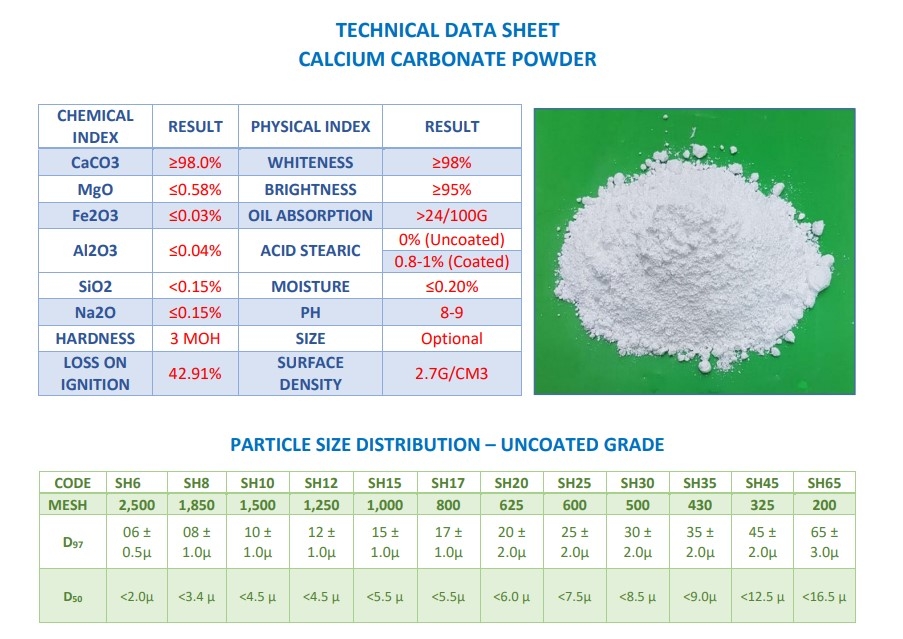

What are the uses of calcium carbonate powder?

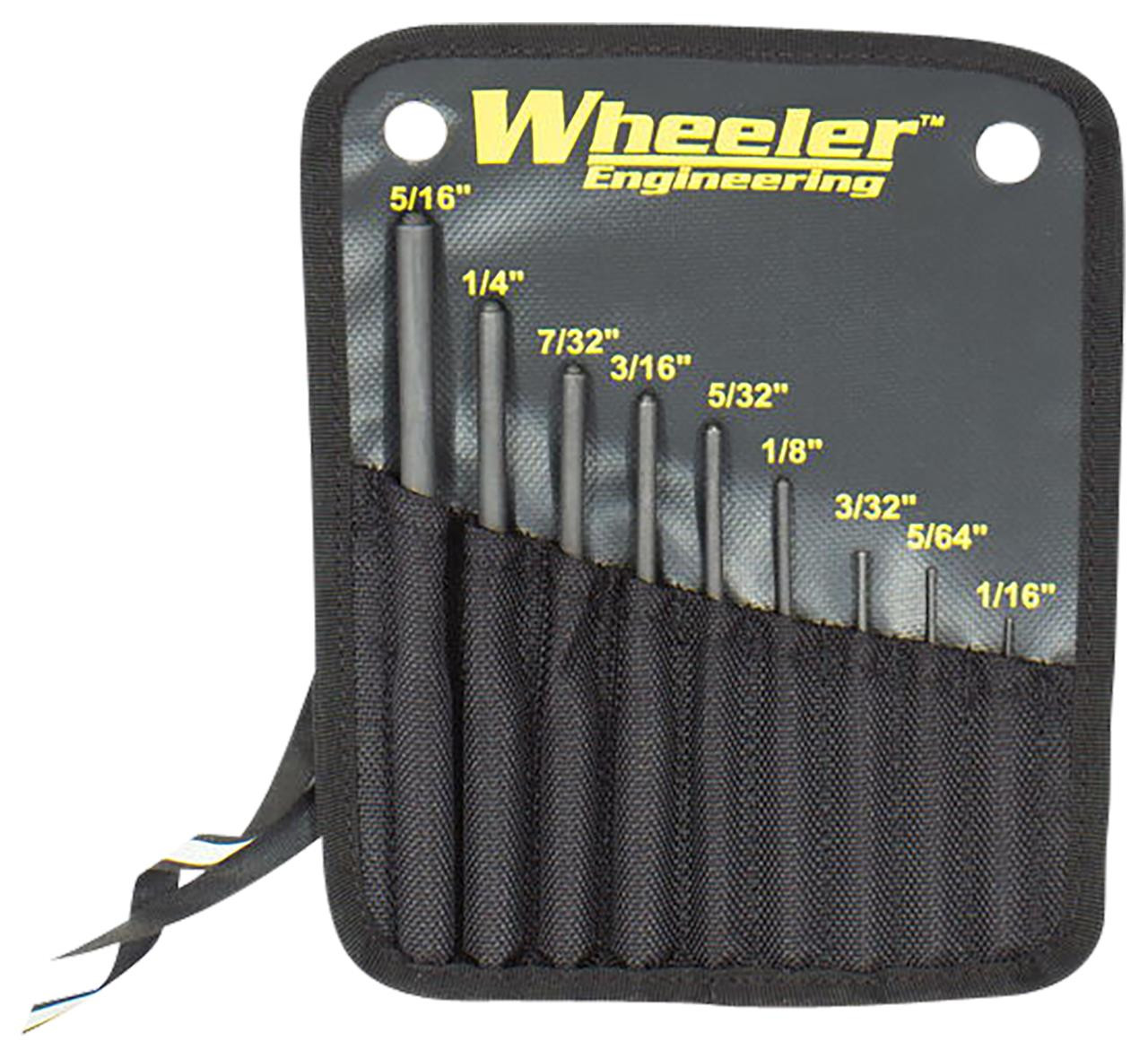

Micro Powder Surface Coating Machine for Calcium Carbonate/Kaolin/Vermiculite/Graphite/Silicon Mirro Powder - China Calcium Carbonate Powder Coating Machine, Calcium Carbonate Powder Surface Coating Mill

Micro Powder Surface Coating Machine for Calcium Carbonate/Kaolin/Vermiculite/Graphite/Silicon Mirro Powder - China Calcium Carbonate Powder Coating Machine, Calcium Carbonate Powder Surface Coating Mill

Why Should Calcium Carbonate be Surface Coated?

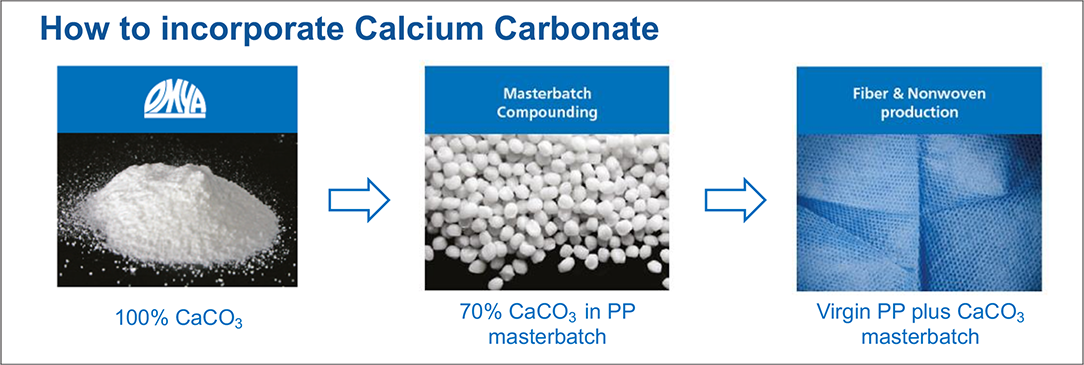

COATED CALCIUM CARBONATE – WHY DO WE COAT IT?

Micro Powder Surface Coating Machine for Calcium Carbonate/Kaolin/Vermiculite/Graphite/Silicon Mirro Powder - China Calcium Carbonate Powder Coating Machine, Calcium Carbonate Powder Surface Coating Mill

PDF] SURFACE-COATED CALCIUM CARBONATE PARTICLES, METHOD FOR MANUFACTURING SAME, AND ADHESIVE BACKGROUND OF THE INVENTION

Calcium carbonate: controlled synthesis, surface functionalization, and nanostructured materials - Chemical Society Reviews (RSC Publishing) DOI:10.1039/D1CS00519G

How to ensure a successful tablet coating formulation development by using polyvinyl alcohol and HPMC in combination with calcium carbonate as a titanium dioxide alternative - Pharma Excipients

The effect of coated calcium carbonate using stearic acid on the recovered carbon black masterbatch in low-density polyethylene composites