Benefits of Using Glass Bead as an Abrasive in Your Blasting Project

In this articlke we explain the benefits that glass beads offer a viable and cost-effective alternative to abrasive for blasting - contact KUE today.

KUE Group specialise in steel surface preparation for NDT. Our services include grit-blasting, paint coatings, linings and corrosion protection for the power generation industry.

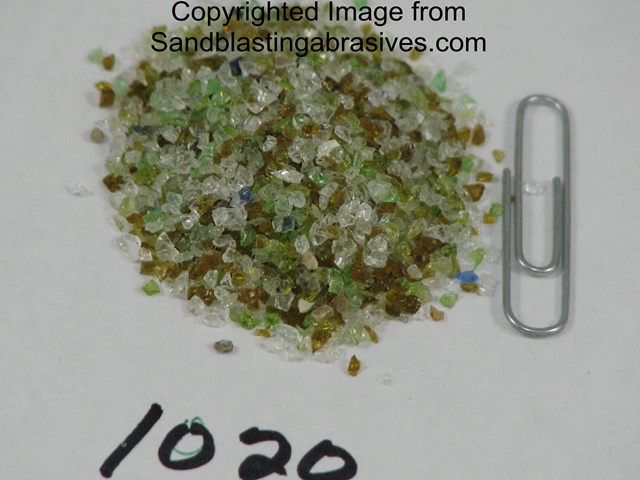

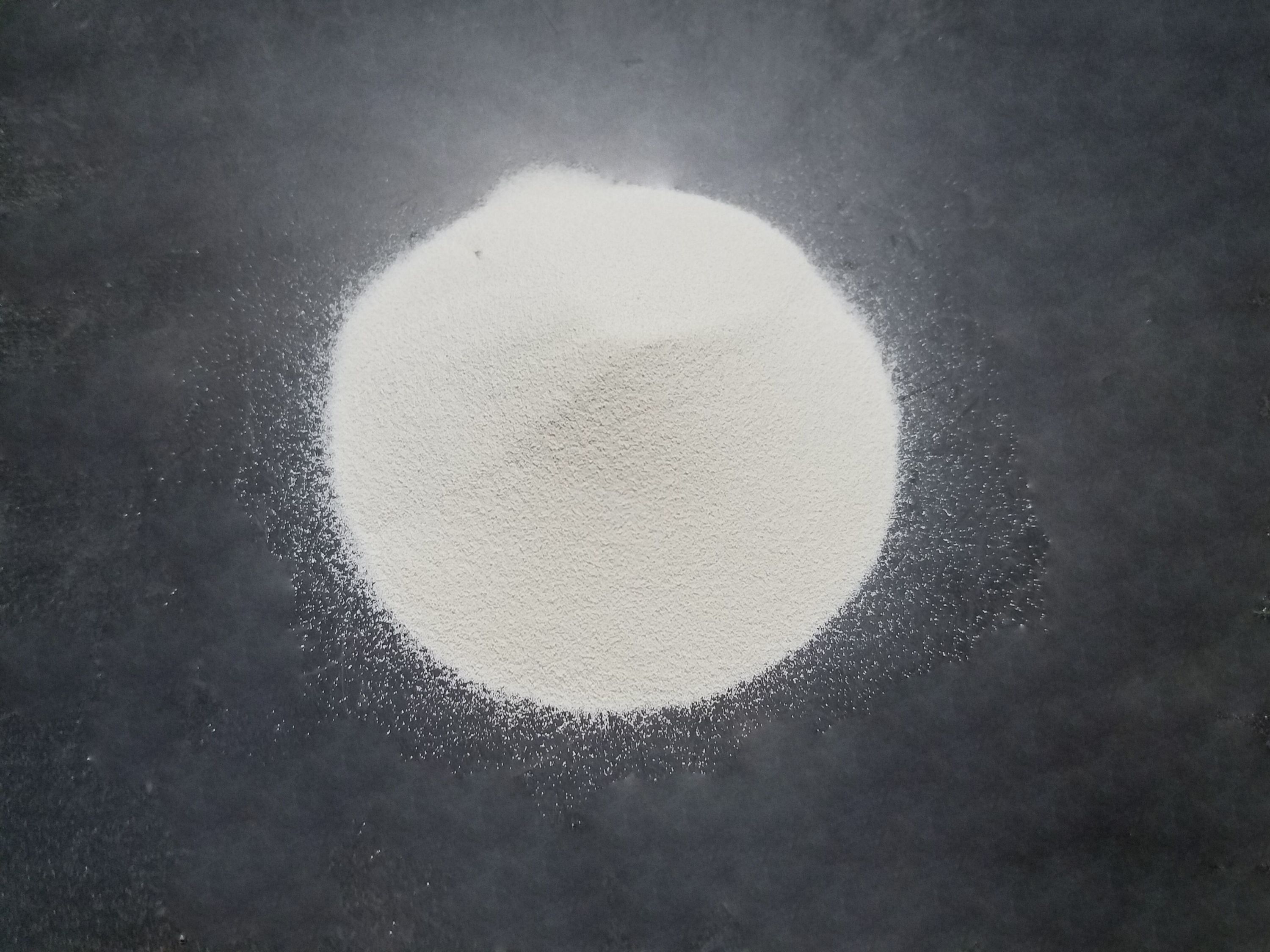

Crushed Glass Sandblasting Media - Nationwide Shipping from many

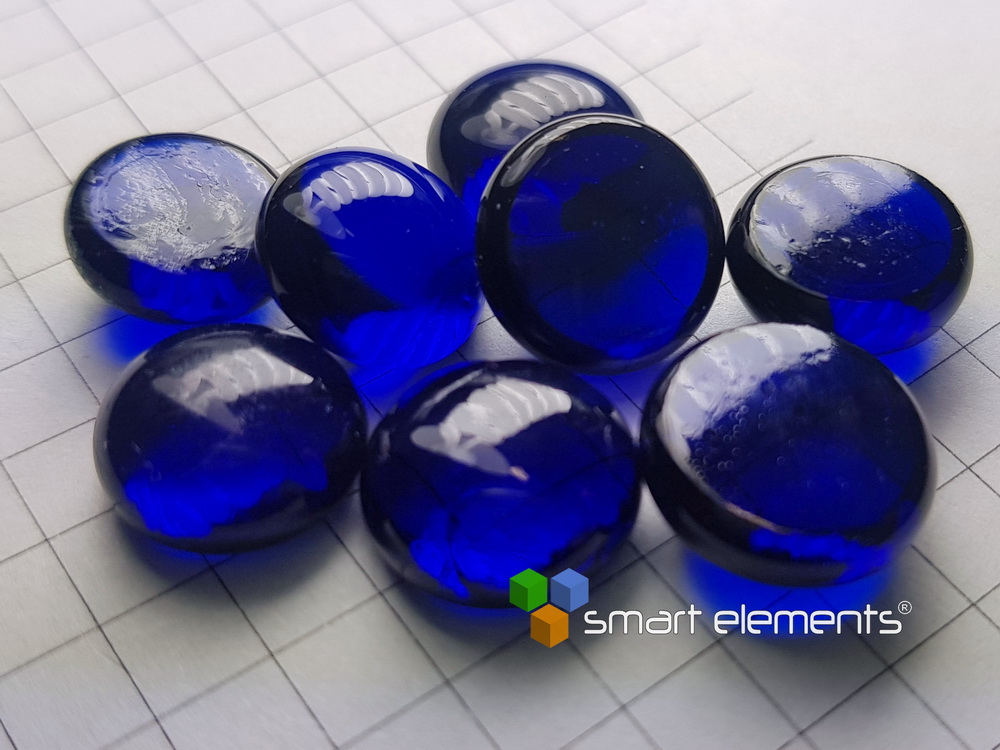

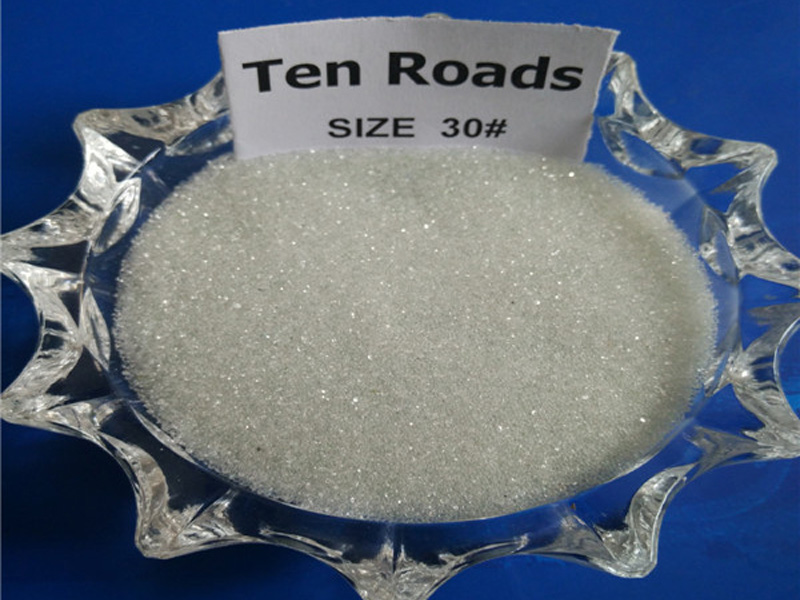

Glass Bead Blasting Media Glass Bead Abrasives SurfacePrep

Glass Bead Blasting Media Glass Bead Abrasives SurfacePrep

The Finished Part: Glass Bead vs Aluminum Oxide Grit

Glass Bead Blasting Media Glass Bead Abrasives SurfacePrep

Sandblasting vs Glass Bead Blasting: Which is Better?

China Glass beads with refractive indexes of 1.9 and 2.2

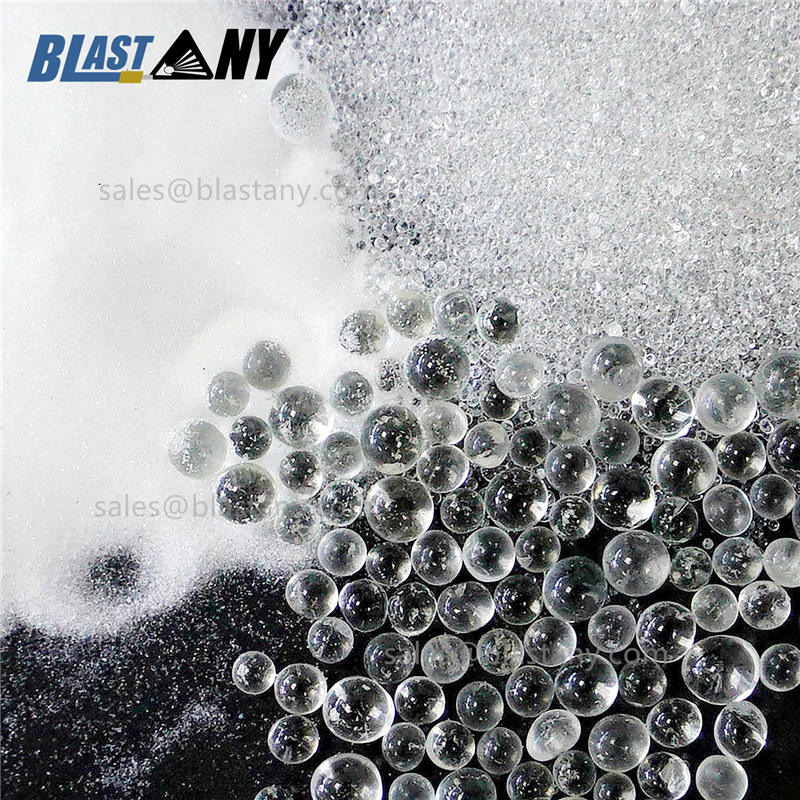

What is Abrasive Blasting? What Media Blast Should I Use?

Glass beads blasting: Pros and Cons

Choosing the Right Media for Vapor Blasting

Waterjetting vs. Abrasive Blasting - VertiDrive - Magnetic Robot

Benefits Of Using Glass Bead As An Abrasive In Your Blasting Project

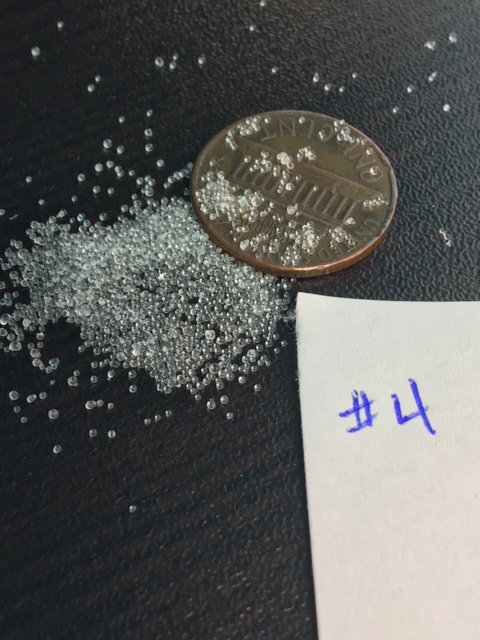

30/60/80/100 Grit Glass Bead Abrasive Media, Glass Bead Sand

When Should You Use Abrasive Blasting

What Particles To Use In Sandblasting? - Protoblast